Hardness testing frameworks

Hardness testing frameworks give a brisk and conservative method of testing properties; everything substances can be tested for hardness gave the right method of test is embraced. The testing offers significant data for exploration and creation applications where substance attributes are significant thought.

The testing gauges substances protection from space and is a decent reference for properties, for example, protection from the scraped spot. Ordinary applications are for car heat treatment examines, defensive and hard covering applications in aviation, and weld review in cutting edge creations. In this article, we plan to take a gander at the five principle kinds of testing, their set of experiences, and a short depiction of their mechanical applications.

Rockwell

One of Rockwell’s principal qualities is the little region of space required, not at all like the Brinell test. It is likewise a lot simpler to use as readings can be given legitimately, without the requirement for complex estimations and conditions.

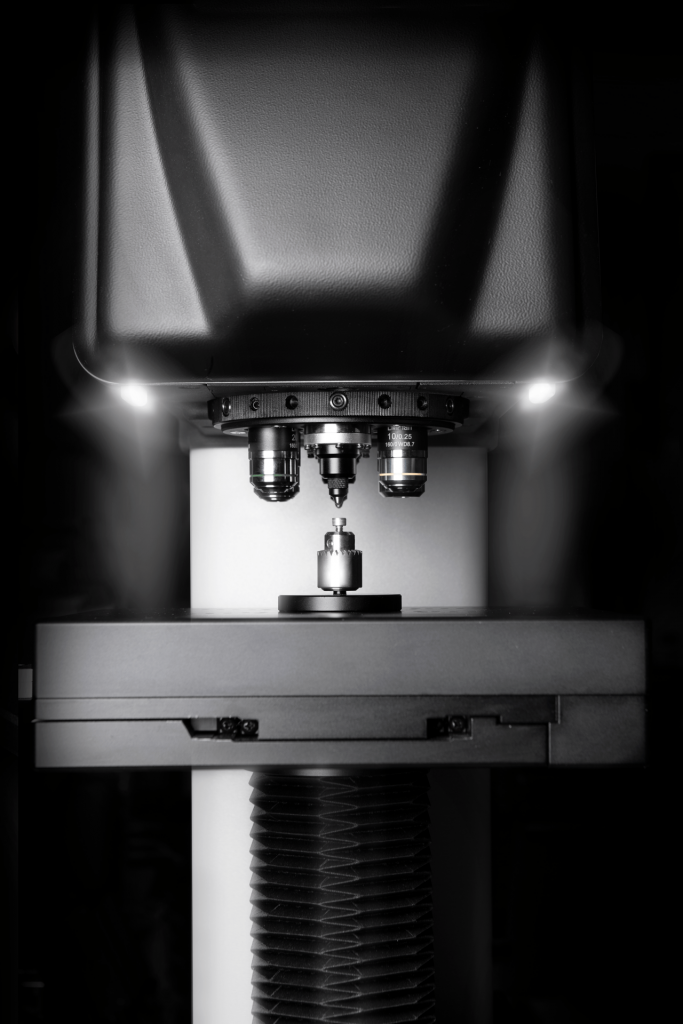

Vickers

The Vickers hardness test was initially evolved as an option compared to the Brinnell test, which was viewed as rather erroneous and restricted in application. The subsequent Vickers test then again held a similar cycle as the Brinell. By utilizing a pyramid formed precious stone instead of a steel ball indenter, they had the option to convey a more reliable and adaptable testing.

Knoop and Microhardness

The diminutive hardness test standard is equivalent to utilized for the Vickers with loads under 1 Kg, and an office to quantify indents at magnifications up to 1000x can be required. The test is also slower than the Vickers test, generally taking a similar time as a Brinell testing.

Brinell

This is the principal method of normalizing hardness, from which different hardness measurement methods. The ball is stacked with up to 3000Kg to make an impression or space on the surface; the indent’s size is estimated and changed over to hardness esteem.

Brinell testing is important in foundry applications where inhomogeneous substance testing is required, for example, huge cast iron castings. The huge ball’s benefit is that the hardness of the parts is estimated over a scope of microstructural highlights, which empowers predictable hardness esteems to be accomplished. While the Brinell test is viewed as less adaptable than that others, it is more powerful.